Copyright Malcolm Faed. Images and text may only be copied with the permission of the author. This blog includes personal things of interest including electric vehicle conversion. I have documented the conversion of a petrol (gas) powered vehicle to Electric. http://www.austinev.org/evalbum/1149. The blog now documents the conversion of a BMW E30 to electric.

Thursday, 23 April 2009

249kWh/km

Monday, 23 March 2009

Zener - Resistor battery balance circuits

I have had to make a few more Zener- resistor balance circuits as some were not evenly matched and caused 2 batteries to discharge below 13.2 at rest. They should be 13.6v (2x6.8V)

The Zener diode voltages would seem to be too low. I need to fix my adjustable PSU and measure the reverse knee voltage on them to verify the voltage and match them in sets of 4 for charging.

Saturday, 7 February 2009

Tray cover complete

Sunday, 1 February 2009

kWh Meter

Sunday, 23 November 2008

12 volt battery installed

I have used one of the spares as the 12 volt battery for the accessories. To fasten it I bought some 6mm threaded rod (600mm zinc plated for $2 from Hardware and General) .

I cut it to length and bent about 30mm on one end 90 degrees. The bent end goes through a 6mm hole drilled in the base where the original battery went.

The battery is sitting on a rubber mat. The threaded rod and the hold down clamp are covered in heat shrink to prevent any possible abrasion.

.jpg)

All battery interconnects are installed and wiring done.

The cables are 16mm^2 . Overkill but free. The contactors along the side are double pole. These are used to break the battery bank into 12 x 48v blocks and on 24v block. This makes it save to work on. I tested each contactor separately with my cable shears at the ready in case I had made a terrible mistake. Thankfully they were not required. Across any contactor there can only be 48v max so it is safe to work on. The stainless steel battery clamp strips are covered in heat shrink to give as much insulation as possible. Each battery has the zener-resistor balance circuit connected across.

Next step is to put the +- 300v cables and interconnects to the VFD into orange plastic tube. and begin connecting the controls. (throttle, reverse lights, direction switch and VFD display. Then the chargers and fuse holders for the chargers.

Saturday, 15 November 2008

Batteries Installed

Sunday, 9 November 2008

Battery box and VFD installed

Yesterday I installed it and the VFD in the tray. Beneath the trey there are 4 stainless steel square tube cross members to help support the batteries, act as spacers for the bolts to the trey structure and to support the VFD.

Tuesday, 23 September 2008

50 x balance systems.

Tuesday, 2 September 2008

A few notes

- My batteries are on a ship on their way from China. Should arrive mid October.

- Spent Saturday installing the dashboard and stereo. Gotta have good sounds!

- I have located all the important wires in the loom and designed the necessary opto isolating interface. (Reverse, Tacho and Speedo)

- I have permanently wired the brake vacuum pump to the ignition

- Sent plans for battery box to Geoff for fabrication.

Wednesday, 11 June 2008

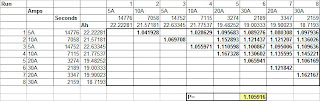

The long awaited 20Ah Greensaver Test Results

Greensaver 20Ah

Apparatus:

Microprocessor controlled battery discharger and charger.

4 x 1 Ohm 200 watt resistors. Hard wire configurable.

Relay to switch between 2 discharge currents

Microprocessor calculates V, I, Temp, Ah, Wh and Peukert Factor.

After discharge, the battery is automatically charged.

The discharge cutoff voltage is programmable.

The negative figures in the LCD indicate that the battery is being charged.

I know, it looks like a weapon of mass destruction :)

Goal:

To determine the Peukert effect of the 20Ah and 27Ah Greensaver battery.

The reason for perform the test is because the specifications state a low Peukert factor fro these batteries and I wanted to verify this before purchasing a pack of 50 batteries.

Results:

Discharge curves. (note glitch in V5 between seconds 3 and 12. As this is only a 9 second occurrence, it does not affect the overall result.

Peukert Effect:

Conclusion:

The average Peukert factor of 1.105 is low compared to other batteries that are usually greater than 1.13 for batteries of similar capacity. The calculated Peukert factor from the 20Ah specification sheet is 1.07. My tester is probably not that accurate but is sufficient to confirm that the battery performs close to specification.

Given this result, if Lead acid batteries are used, they should have superior performance under load and give a long service life.

Original discharge data is available in an Excel sheet upon request.

Next steps:

I also have a 27Ah battery that will be tested next.

The high current wiring will be upgraded to allow testing at 40A

The discharger will also be reprogrammed to continuously charge and discharge a battery to determine de rating over time.

Charging:

The charge curve for the 20Ah battery is below.

Thursday, 29 May 2008

Update - Batteries - Tester - Diff - Steering - VFD - Tray

1. I received the Greensaver batteries (20ah and 27ah - 2 hr rate). The port chargers were unbelievable! These would have to be the 2 most expensive batteries in Australia! Lesson learned about sea-freighting goods

2. I have built a micro controller based charger / discharger. It will measureand log to a PC the following aprameters during discharge and charge Volts, Amps, Watts, Ah, Wh, temperature and the all important Peukert factor. It uses 4 x 1 ohm resistors. The resistors can be wired differently to vary the test current. I am waiting an LCD from Futurelec and a charger from ebay's ecrazyman.

3. I have bought a diff from pick'n'payless . It is a 5.125 ratio from a Hiace van. All going well I will install it this weekend. This gives a theoretical top speed of 94km/hr at 4000RPM

4. I also bought a manual steering box from pick'n'payless for installing this weekend.

5. Better VFD. I bought a better Danfoss 5042 VFD off ebay. So, if anyone wants a Danfoss 6042VFD in an IP54 case I have one looking for a home. I have removed all the AC components from the cabinet to minimise losses and will feed it DC directly to the soft charge circuit.

6. The ute has a tray back which was way too wide for the body. To tidy up the looks I have narrowed the tray to be the same as the body (100mm off each side) and shortened the back. If I need sides I can get them from the manufacturer which is encouraging.

At the moment the carport looks like a car wreckers yard, but things should start coming together in the next few weeks. I am still waiting to borrow an engine hoist from my neighbours.

Saturday, 5 April 2008

Battery Balancer

As there are 50 units the price could be quite significant.

Ideally a microprocessor based system would be implemented with isolated sensors on each battery however at this time it is cost and time prohibitive.

There are 2 alternatives I have seen the first would place 15V Zener Diode in series with a light bulb or suitable resistor across the battery. When a battery exceeds 15 volts, the Zener and lamp would bypass current proportional to the over voltage. This would be the simplest to implement.

Another alternative is a more aggressive voltage clamp described here.

The clamp voltage will have to be above the maximum charge voltage from the chargers and the regenerative braking.

Under regen this is 15 volts. Under charge this is about 15 volts but will need to be measured on the charger.

Obviously this solution will only work under charge but should be sufficient for now.

I will test it on my self balancing scooter first.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)